of 30 September 2016

amending Regulation (EEC) No 2568/91 on the characteristics of olive oil and olive-residue oil and on the relevant methods of analysis

THE EUROPEAN COMMISSION,

Having regard to the Treaty on the Functioning of the European Union,

Having regard to Regulation (EU) No 1308/2013 of the European Parliament and of the Council of 17 December 2013 establishing a common organisation of the markets in agricultural products and repealing Council Regulations (EEC) No 922/72, (EEC) No 234/79, (EC) No 1037/2001 and (EC) No 1234/2007 (1), and in particular point (d) of the first paragraph and the second paragraph of Article 91 thereof,

Whereas:

| (1) | Commission Regulation (EEC) No 2568/91 (2) defines the chemical and organoleptic characteristics of olive oil and olive-pomace oil and lays down methods of assessing those characteristics. Those methods are regularly updated on the basis of the opinion of chemical experts and in line with the work carried out within the International Olive Council (IOC). |

| (2) | In order to ensure the implementation at Union level of the most recent international standards established by the IOC, the method for the determination of the peroxide value set out in Regulation (EEC) No 2568/91 should be updated. |

| (3) | Regulation (EEC) No 2568/91 should therefore be amended accordingly. |

| (4) | The measures provided for in this Regulation are in accordance with the opinion of the Committee for the Common Organisation of the Agricultural Markets, |

HAS ADOPTED THIS REGULATION:

Article 1

Annex III to Regulation (EEC) No 2568/91 is replaced by the text set out in the Annex to this Regulation.

Article 2

This Regulation shall enter into force on the third day following that of its publication in the Official Journal of the European Union.

This Regulation shall be binding in its entirety and directly applicable in all Member States.

Done at Brussels, 30 September 2016.

For the Commission

The President

Jean-Claude JUNCKER

(1) OJ L 347, 20.12.2013, p. 671.

(2) Commission Regulation (EEC) No 2568/91 of 11 July 1991 on the characteristics of olive oil and olive-residue oil and on the relevant methods of analysis (OJ L 248, 5.9.1991, p. 1).

ANNEX

‘ANNEX III

DETERMINATION OF PEROXIDE VALUE

1. Scope

This Annex describes a method for the determination of the peroxide value of animal and vegetable oils and fats.

2. Definition

The peroxide value is the quantity of those substances in the sample, expressed in terms of milliequivalents of active oxygen per kilogram, which oxidise potassium iodide under the operating conditions described.

3. Principle

Treatment of the test portion, in solution in acetic acid and chloroform, by a solution of potassium iodide. Titration of the liberated iodine with standardised sodium thiosulphate solution.

4. Apparatus

All the equipment used must be free from reducing or oxidising substances.

Note 1: Do not grease ground surfaces.

| 4.1. | 3 ml glass scoop. |

| 4.2. | Flasks, with ground necks and stoppers, of about 250 ml capacity, dried beforehand and filled with a pure, dry inert gas (nitrogen or, preferably, carbon dioxide). |

| 4.3. | Burette of 5-ml, 10-ml or 25-ml capacity, graduated in at least 0,05 ml, preferably with automatic zero adjustment, or equivalent automatic burette. |

| 4.4. | Analytical balance. |

5. Reagents

| 5.1. | Chloroform, analytical reagent quality, freed from oxygen by bubbling a current of pure, dry inert gas through it. |

| 5.2. | Glacial acetic acid, analytical reagent quality, freed from oxygen by bubbling a current of pure, dry inert gas through it. |

| 5.3. | Potassium iodide, saturated aqueous solution, recently prepared, free from iodine and iodates. Dissolve approximately 14 g of potassium iodide in approximately 10 ml of water at room temperature. |

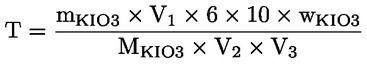

| 5.4. | Sodium thiosulphate, 0,01 mol/l (equivalent to 0,01 N) accurately standardised aqueous solution, standardised just before use. Prepare daily the 0,01 mol/l sodium thiosulfate solution freshly from a 0,1 mol/l sodium thiosulfate standard solution before use, or determine the exact molarity. As experience shows, the stability is limited and depends upon the pH value and the content of free carbon dioxide. Use only freshly boiled water for the dilution, possibly purged with nitrogen. The following procedure is recommended to determine the exact molarity of the sodium thiosulfate solution: Weigh, to the nearest 0,001 g, 0,27 g to 0,33 g of potassium iodate (mKIO3) into a volumetric flask (250 ml or 500 ml) and dilute to the mark with freshly boiled water (V2), cooled down to room temperature. By means of a pipette, transfer 5 ml or 10 ml of this potassium iodate solution (V1) into a 250 ml Erlenmeyer flask. Add 60 ml of freshly boiled water, 5 ml of 4 mol/l hydrochloric acid, and 25 mg to 50 mg of potassium iodide or 0,5 ml of the saturated potassium iodide solution. Titrate this solution with the sodium thiosulfate solution (V3) to determine the exact molarity of the sodium thiosulfate solution.

Where

|

| 5.5. | Starch solution, 10 g/l aqueous dispersion, recently prepared from natural soluble starch. Equivalent reagents may also be used. |

6. Sample

Take care that the sample is taken and stored away from the light, kept cold and contained in completely filled glass containers, hermetically sealed with ground-glass or cork stoppers.

7. Procedure

The test must be carried out in diffuse daylight or in artificial light. Weigh in a glass scoop (4.1) or, failing this, in a flask (4.2), to the nearest 0,001 g, a mass of the sample in accordance with the following table, according to the expected peroxide value:

| Expected peroxide value (meq) | Weight of test portion (g) |

| 0 to 12 | 5,0 to 2,0 |

| 12 to 20 | 2,0 to 1,2 |

| 20 to 30 | 1,2 to 0,8 |

| 30 to 50 | 0,8 to 0,5 |

| 50 to 90 | 0,5 to 0,3 |

Unstopper a flask (4.2) and introduce the glass scoop containing the test portion. Add 10 ml of chloroform (5.1). Dissolve the test portion rapidly by stirring. Add 15 ml of acetic acid (5.2), then 1 ml of potassium iodide solution (5.3). Insert the stopper quickly, shake for one minute, and leave for exactly five minutes away from the light at a temperature from 15 to 25 °C.

Add about 75 ml of distilled water. Titrate the liberated iodine with the sodium thiosulphate solution (5.4) shaking vigorously, using starch solution (5.5) as indicator.

Carry out two determinations on the same test sample.

Carry out simultaneously a blank test. If the result of the blank exceeds 0,05 ml of the 0,01 N sodium thiosulfate solution (5.4), replace the impure reagents.

8. expression of results

The peroxide value (PV), expressed in milliequivalents of active oxygen per kilogram, is given by the formula:

where:

| V | = | the number of ml of the standardised sodium thiosulphate solution (5.4) used for the test, corrected to take into account the blank test. |

| T | = | the exact molarity of the sodium thiosulphate solution (5.4) used, in mol/l. |

| m | = | the weight in g, of the test portion. |

Take as the result the arithmetic mean of the two determinations carried out.

Report the result of the determination to one decimal place.’